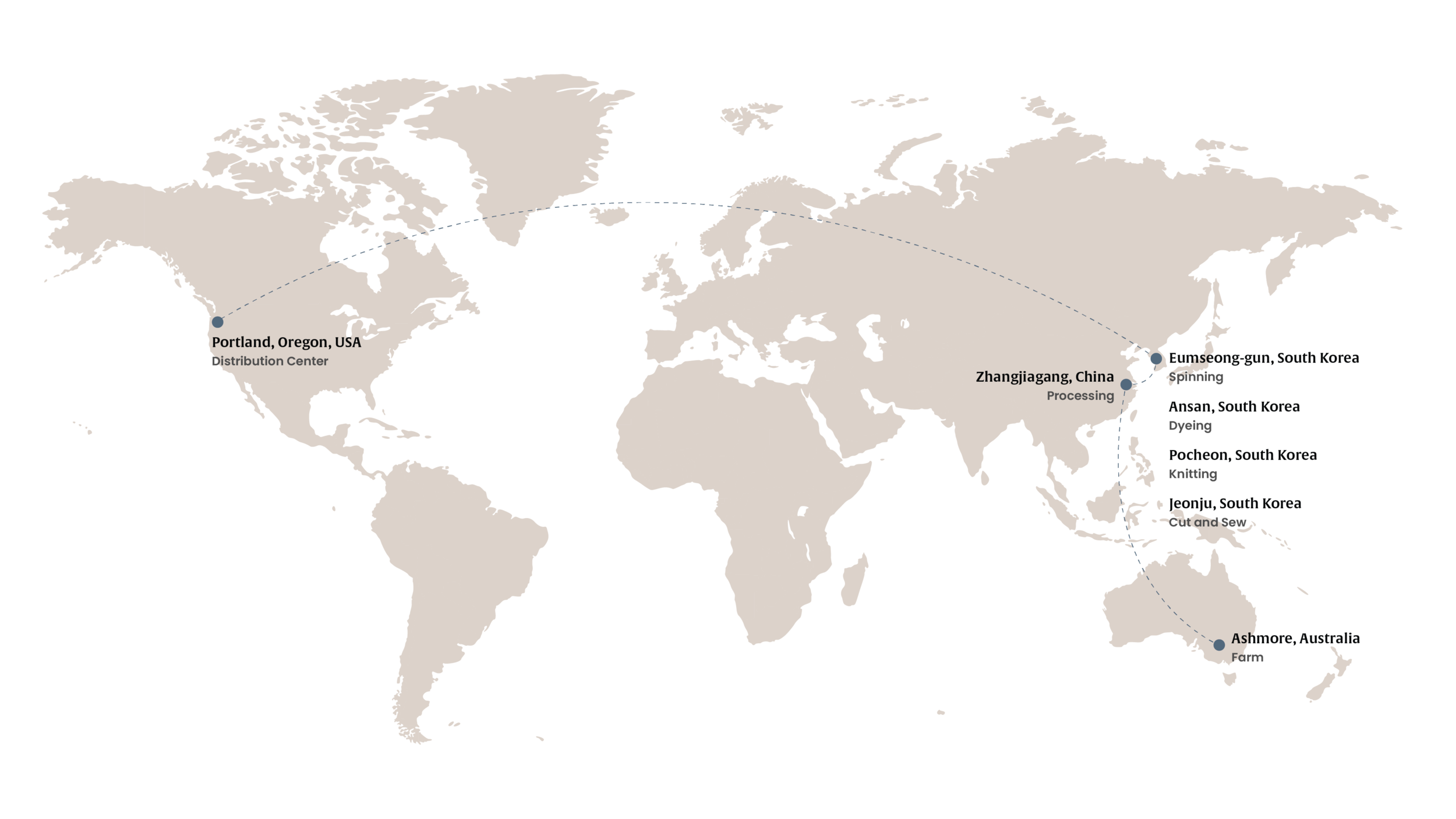

Supply Chain

Our Supply Chain

Live simply.

Consume carefully.

Do good.

OUR MATERIALS & FARMs

We’re not here to tell you that buying a dress will save the planet; it won’t. Instead, we want to share our progress in building a more thoughtful, slow fashion apparel company. We’re founded on the idea that women get more out of life when they have fewer things. That’s why we design the most practical, most wearable item in your wardrobe.

Our Materials

Sunshine. Rain. Grass. Fresh Air. These are the foundations of your wool& item. Our favorite natural material wool is renewable and biodegradable. When needed, we add other materials (like nylon) to increase durability, so your dress lasts longer and is easier to care for.

We directly source wool from the McBride family farm, based in Australia. The remainder of our wool is sourced on the “open market” from Australian farms that follow recognized animal welfare standards.

Our Farm Partner

We partner with the McBride farm, who have been growing wool in Australia for over 100 years. As a family-run organization, the McBrides are in the business of creating a sustainable company for generations to come. The farm is specifically focused on improving energy efficiencies, land conservation, and biodiversity. The Woolmark Company, the global authority on Merino wool, introduced us to the McBride Family.

“We take on the responsibility of preserving the environment for future generations, and our aim is to leave the land and its natural resources in a better state than we acquired them.”

History of the Ashmore Farm

The southeast of South Australia is known for its rich soils and high rainfall, which makes it ideal for grazing operations. The farmland at the Ashmore Station is mostly flat, and features underground water capable of providing irrigated pastures.

The Ashmore Station

Kingston SE, South Australia

7 Employees

18,172 Acres

Animal Welfare

One of the values of our company is to “do better,” and we are committed to being a changemaker in the wool industry. A part of being a changemaker is to observe how certain practices are currently being carried out, and actively working to improve them. Our goal is to be part of the solution to reduce the practice of mulesing in the long-term. The McBrides are transitioning away from mulesing through the use of selective breeding and active management to control flystrike, a deadly parasitic infection. This takes time to safely suppress in a flock without the use of heavy chemicals. As a result of our work with this farm, they are committing more resources to accelerating their transition away from mulesing. By the end of 2024, the McBrides have committed to cease mulesing. We’re proud of our partnership with the McBrides – a unique opportunity for a small business like ours to drive change in the wool industry and develop a direct relationship with a farm.

September 2024 Update:

The McBrides ceased mulesing at three of their properties that produce coarser wools; however, they've been unable to meet our 2024 timeline at Ashmore. We will return to sourcing certified non-mulesed wool on the open market. When Ashmore ceases mulesing, we look forward to buying wool from the McBrides again and sharing their amazing story and commitment to the land. We're proud of the work we've done with the McBrides and we're proud of our customer transparency even when it's not a "win".

August 2023 Update: The McBrides are on target to stop mulesing by the end of 2024.

August 2022 Update: We spoke with our farm in August 2022 about their progress transitioning away from the practice of mulesing, and they are on target to supply us with only non-mulesed wool by the end 2024. Once complete, they're confident that their daily operation will check all of the other RWS (Responsible Wool Standard) guidelines and they will be RWS certified.

Factories

Our partners—like us—are committed to making better, longer-lasting apparel. We’ve built trusting relationships and have been working with our knit and woven partners since 2013.

Spinning and Knitting Mill

-Location: Eumseong-gun, South Korea

-Number of employees: 80 spinning, 20 knitting

-Certification: Woolmark License

Dye House

-Location: Ansan, South Korea

-Number of employees: 86

-Certification: ISO9001, GRS

Knit Cut & Sew Factory

-Location: Jeonju, South Korea

-Number of employees: 40

-ISO Certifications: 14001 (Environmental Management), 9001 (Quality Management), and ISO45001 (Occupational Health and Safety Management)

South Korea is a developed country with strict labor laws requiring:

Medical Insurance

Occupational Health and Safety Insurance

Employment Insurance

National Pension

20 days of covered vacation per year

Employees at our factory start earning an hourly wage at around 24% above the South Korean minimum wage

Woven Mill

-Location: Changzhou (2 hours outside of Shanghai)

-Number of employees: 1000

-Certification: OEKO-TEX® STANDARD 100

-Campus: 9 acres

Woven Shirting Cut & Sew Factory

-Location: Ningbo (2.5 hours outside of Shanghai)

-Number of employees: 150

-Campus: 4 acres

-Certification: ISO9001:2000

-Product examples: Laurel, Florence

Specialty Cut & Sew Factory

-Location: Shenzhen (2 hours outside of Hong Kong)

-Number of Employees: 150

-Campus: 30,000 sq ft

-BSCI (Business Social Compliance Initiative)

-Product examples: Penny, Greta, Hilltop

Knitting Mill

-Location: Melton, Victoria Australia

-Number of Employees: 70

-Campus: 25 acres

-Certifications: OekoTex 100, Australian Certified Organic, ISO9001 – Quality Management System, ISO14001 – Environmental Management System, Responsible Wool Standard – Fully Certified

-Product examples: 100% wool Cara tee, Lou Ponte Moto Jacket, Frame Ponte Culottes

Sewing Factory:

-Location: Ho Chi Mihn City, Vietnam

-Number of Employees: 990

-Campus: 1.25 acres

-Certifications: SA8000 and OekoTex 100

-Product examples: 100% wool Cara tee, Lou Ponte Moto Jacket, Frame Ponte Culottes